Forging Twisting Machine MT500a

Product Details:

- Product Type Forging Twisting Machine

- Output depends on material

- Raw Material MS,SS

- Bending Strength dependings upon size

- Bending Speed 10 rpm

- Voltage 415 Volt (v)

- Power 415 Volt (v)

- Click to View more

Forging Twisting Machine MT500a Price And Quantity

- 1 Piece

- 1654491 INR/Piece

Forging Twisting Machine MT500a Product Specifications

- 1351 Kilograms (kg)

- dependings upon size

- Red & Black

- semi automatic

- Twisting & Scroll

- spain

- Industrial

- 415 Volt (v)

- 10 rpm

- 415 Volt (v)

- Forging Twisting Machine

- depends on material

- MS,SS

- dependings upon size

Forging Twisting Machine MT500a Trade Information

- Ex works Bangalore

- Cheque

- 1 Piece Per Week

- 10 Week

- Contact us for information regarding our sample policy

- Wooden Box

- Asia Middle East

- All India

- ISO & CE

Product Description

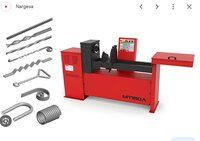

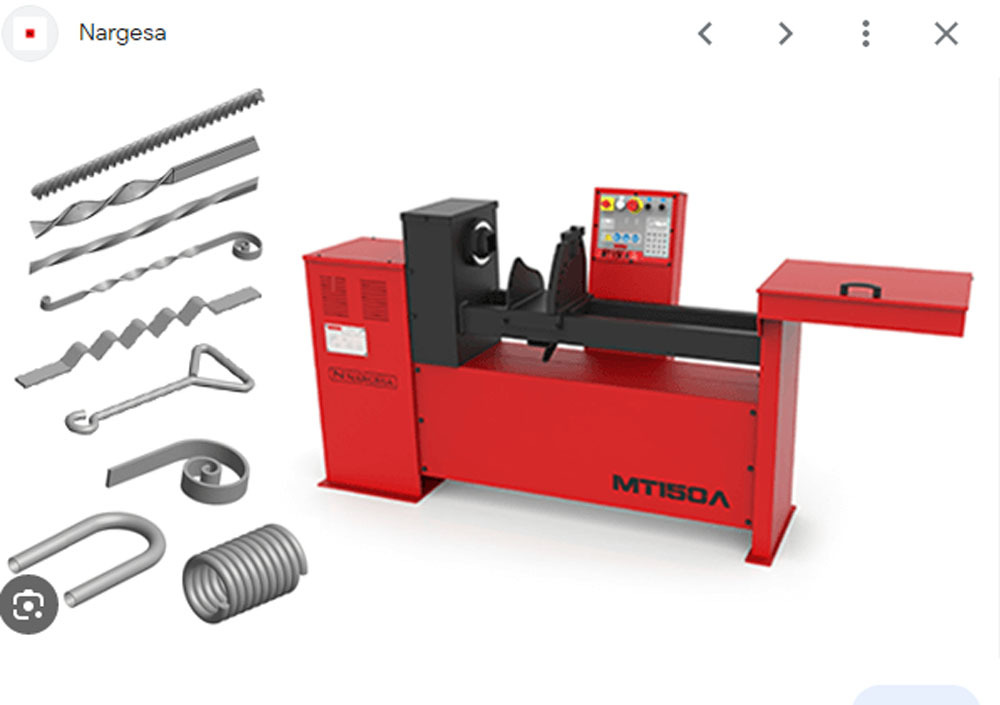

The twisting machine MT500A Nargesa was patented by Nargesa many yeasr ago. It makes us lead the manufacturing of this kind of machinery. It is made in a welded and mechanized Steel monoblock. It has been thought to transform cols iron.

Working method by twisting and flexion inCOLD.

Machine suitable for small,medium and big productions.

Safe and reliable transmision by a motor reducer with treated flat pinions, acomplishing a great performance with little maintenance.

Its perfect for making all kind of standard ornamental pieces and essencial to make your own designs which are much more demanded in the market.The pieces as requested by architects, technicians and final users make it an indispensable tooling in a blacksmith workshop.

It''s got two working sites,one for twisting and another one for bending with no neck limit. It means big sized pieced can be made, unlike in other machines of this kind in the market..

In order to make this kind of special jobs, Nargesa provides you under request either the tooling or the fitting discs so the very customer can create his own designs.

The forging equipment Nargesa MT500Ais equipped with a set of tooling by means of which a great number of pieces can be made: Twisting, scrolls, hooks, chains... (More information atSTANDARD TOOLINGat the bottom of the page).

There is also the possibility of purchasing optional tooling:Belly Top Railing, British Rail, Flat bent rings, ornamental baskets... (More information atOPTIONAL TOOLINGat the bottom of the page).

Technical Characteristiques

Maximum twisting Capacity40 mm or 1 3/8" inches.

Maximum bending capacity:25 mm or 1" inches.

Maximum scrolling and bending capacity in flat bar, clod or hadrail 50x10 mm or 2"x 3/8" inches.

Possibility of buying the tooling for the machine in mm or inches.

Max. continuous twisting length:1.620 mm.

MOtor power: 4Kw / 5,5 HP.

CNC programmer to make high productions.

3-phased tension: 230/400 V.

Adjustable rotation speed from 0 to 10 r.p.m..

Palletized lower bench to move the machine easily to the working site or storage.

The machine is delivered completely assembled.

Packing with fumigated wooden palletNIMF 15and 3-layered cardboard box suitable for sea freight.

Optional: COmplete wooden packing withNIMF15.

Its robustness, versatility, cotrol programmer, productivity and easy handling, make it one of the best machines for a blacksmith workshop.

All our products are manufactured in our facilities in Spain. Hydraulic and elec tronic components are completely standard from the best European leading trademarks with technnical support all over the world:Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Profile Bending Machines' category

Talleres GAMOR, S.L.

Ind. Asteasu Zona E Pab.73-74,

20159 Asteasu Guipuzcoa, Spain

|

GA-MOR MACHINE TOOLS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese